Robotic precision meets pharmaceutical demand

To address growing medicines shortages across Europe, Robotronic partnered with Mitsubishi Electric to revolutionise pharmaceutical packaging with cutting-edge robotics. By combining compact design, compliance control, and unmatched precision, they delivered a solution that ensures maximum productivity without compromising safety. This collaboration highlights how automation and robotics can solve critical supply chain challenges in the pharmaceutical industry.

Challenge: Meeting pharmaceutical demand with precision and safety

Pharmacies across Europe are facing shortages of essential medicines, particularly children’s cough syrups. Increased demand is leaving shelves empty, calling for faster production and efficient packaging solutions. Robotronic, a Swiss company specialising in robotic applications for the pharmaceutical industry, needed to design compact, high-performance machines capable of handling fragile glass vials with precision and zero product damage—all while maintaining strict regulatory compliance.

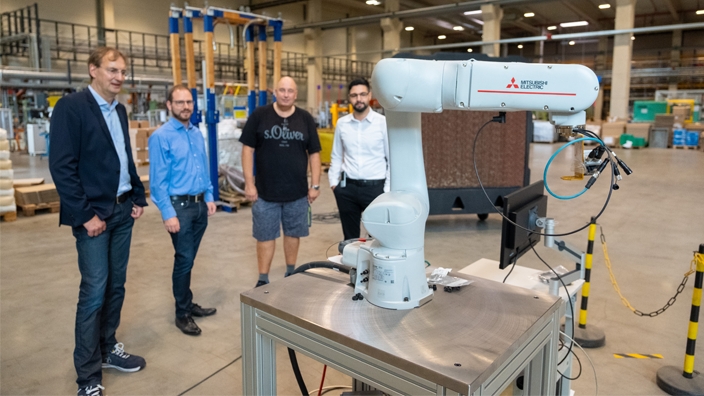

Solution: Compact, innovative robotics

Robotronic, in collaboration with Mitsubishi Electric, developed a solution that combines advanced robotics with a focus on safety, speed, and precision.

Key features of the solution include:

- Mitsubishi Electric MELFA FR series robots: Compact design with flexible arm sizes to minimize footprint while maximizing productivity.

- Compliance control technology: Ensures a “soft touch” when handling fragile glass vials, reducing the risk of damage to zero.

- Dual-robot operation: Enables two robots to work in confined spaces with millimetre-level precision, avoiding collisions while maintaining high speeds.

- Integrated automation: Utilisation of Mitsubishi Electric servos, GOTs, and PLCs to ensure seamless and reliable machine performance.

Result: High-speed, damage-free production

- Zero product damage: Compliance control technology ensures gentle handling of glass vials, eliminating breakage.

- Compact and efficient design: Machines operate in minimal space (as small as 120 x 80 cm) while handling up to 600 products per minute.

- Seamless dual-robot operation: Robots work side by side with unmatched precision, maintaining consistent performance over years of operation.

- Regulatory compliance: The solution meets strict pharmaceutical industry standards for safety and quality.

Why it matters

This project demonstrates how advanced robotics and strong partnerships can address critical challenges in the pharmaceutical industry. By combining Robotronic’s expertise in pharmaceutical processes with Mitsubishi Electric’s cutting-edge robotics, the collaboration delivered a solution that not only increases productivity but also ensures safety and reliability. As medicines shortages persist, such innovations are crucial for maintaining a resilient and efficient supply chain.

Have we sparked your interest? Contact us

Our Stories

#Manufacturing#Industrial Robots - MELFA

#Automotive#Digitalisation#Industrial Robots - MELFA

#Food & Beverage#Machine Building#AC Servos-MELSERVO#Human-Machine Interfaces (HMIs) - GOT#Industrial Robots - MELFA#Controllers

Guarda il video su YouTube#Automotive#Material Handling#Controllers#Human-Machine Interfaces (HMIs) - GOT#Industrial Robots - MELFA